General Engineering

Precision solutions for diverse industries, enhancing functionality and performance.

View more

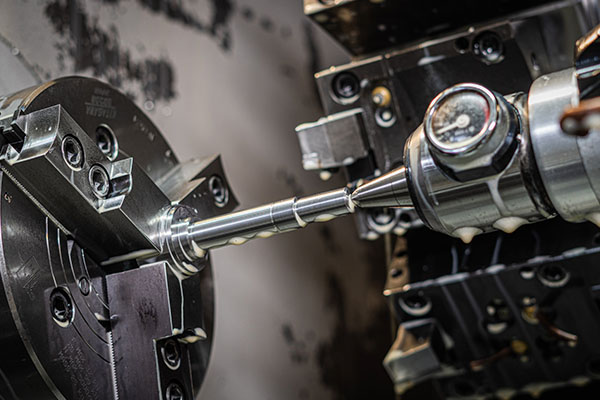

MK CNC Engineering utilises state-of-the-art manufacturing technology to provide custom services that transform your dream into reality. Our highly skilled team is committed to providing exceptional manufacturing solutions tailored to your specifications.

Welcome to MK CNC Engineering, a premier precision engineering and manufacturing solutions provider. With a strong foundation built on years of industry experience, we specialise in delivering high-quality CNC engineering work tailored to meet the diverse needs of our clients across various sectors. Our commitment to innovation, quality, and customer satisfaction sets us apart in the engineering landscape.

M K CNC Engineering- we transform your Business into reality through high-quality Manufacturing Engineering Services. We take complete pride in delivering precision and quality-specific CNC engineering services according to our customers’ needs. Our in-house advanced manufacturing technologies are used in our custom machine shop to provide engineered solutions for any complexity in CNC machining.

M K CNC Engineering designs to support your unique manufacturing and engineering needs. Our expertise in drilling, turning, and milling, makes every project easy for us. The latest manufacturing engineering strategies guarantee accuracy, reliability, and innovation in all the services. We provide precision CNC milling machining solutions tailored for the aerospace, mining, and defense industries.

Don’t wait—let’s create precise-engineered solutions that set you apart. Contact Us Today!

Precision solutions for diverse industries, enhancing functionality and performance.

View more

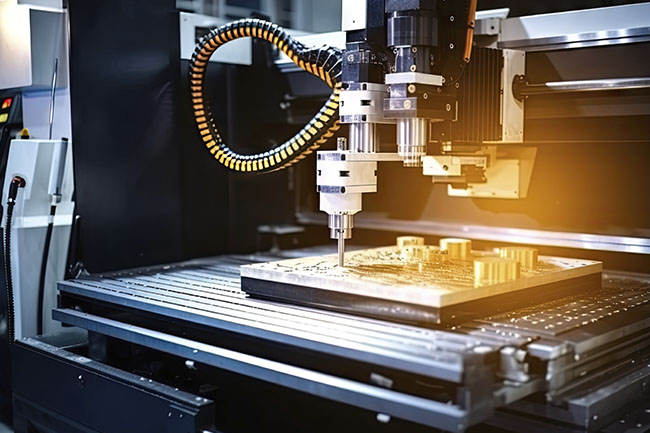

We offer a comprehensive range of processing options tailored to meet the unique needs of our customers. Our state-of-the-art facilities enable us to provide top-quality services, including :

Years of experience and mastery in CNC engineering from our engineers and technicians give you high-quality results in every project.

We continually invest and update advanced manufacturing technology to optimise our processes, making them more efficient and providing superb manufacturing services.

Quality control measures are ensured throughout the manufacturing process so every product meets or exceeds expected industry standards.

Our team keeps you aware of each step of production, so you can stay satisfied that your project is in process.

M K CNC Engineering is committed to serving various industries that use precision-driven manufactured solutions. The company possesses the skills and manufacturing technologies to cater to specific needs in each sector with unique challenges, resulting in reliable and quality outputs.

Our CNC machining services consider various metallic, plastic, and composite materials to address a full range of materials involved, depending on the specific client project.

Lead times differ based on the complexity and dimension of the project. Our speed is prioritised since we will stay in touch with you to set a timeline geared toward making it all work for you.

Yes! From small prototype runs to massive runs, we can handle any size project consistently and efficiently.

Certainly! Our professional engineering team is available to partner with you to develop an exact version of the custom CNC machining services that fit the needs of your program.

What separates us from the rest all boils down to quality, innovation, and customer satisfaction. Advanced manufacturing technology plus a team of skilled professionals allow us to provide custom solutions that perfectly meet your specific needs.

Contact us, and we’ll discuss your needs and how our manufacturing solutions can take you higher. Let’s turn ideas into products that are built to precision!