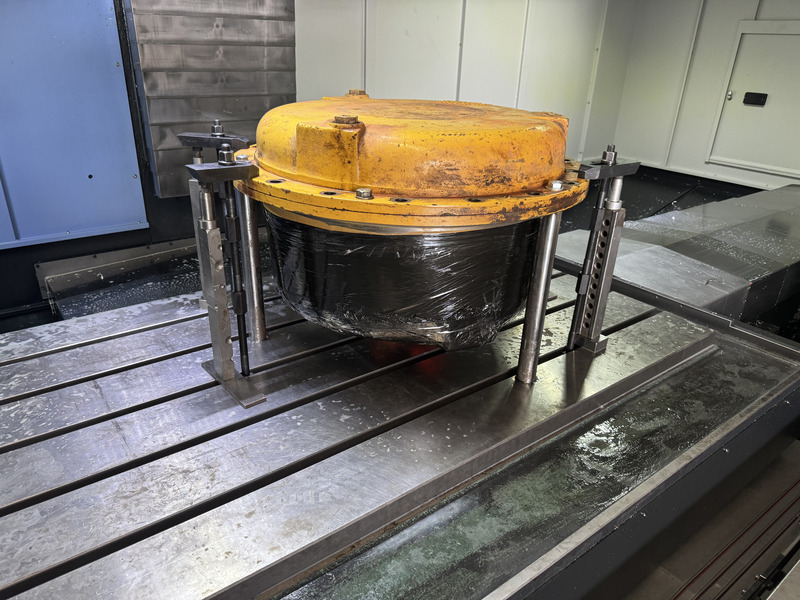

Our CNC machining services for mining ensure the production of reliable, high-performance parts and tools essential to mining operations. From CNC lathes and mills to advanced drills, we provide mining equipment machining that withstands harsh environments while delivering exceptional durability and precision.

Precision CNC machining is vital in manufacturing components like gears, sprockets, which are integral to mining equipment. Our CNC services for mining produce durable and efficient parts to maximise equipment performance and minimise downtime.

At MK CNC Engineering, we specialise in delivering customised CNC mining industry solutions. Whether creating custom parts for repairs or developing components for specialised equipment, our expertise ensures fast turnaround and exact tolerances, reducing operational delays and optimising productivity.

CNC machining for mining offers numerous benefits, including:

High levels of accuracy ensure consistent quality for critical components.

Parts are built to withstand extreme conditions, enhancing equipment longevity.

Advanced automation reduces waste and improves manufacturing efficiency.

Our services cater to unique operational needs, enabling modifications to materials, designs, and specifications.

With years of experience in the mining sector, MK CNC Engineering has built a reputation for excellence in mining equipment machining. Our team understands the unique challenges of the industry and provides solutions to meet diverse client needs.

We use cutting-edge CNC lathes, mills, and drills to manufacture parts with tight tolerances and exceptional accuracy. It ensures optimal performance and reliability in mining operations.

Our mining tools and spare parts are designed for diverse applications across various mining sectors. From coal mining and metal extraction to mineral processing, quarrying, and excavation, we deliver solutions to meet the unique demands of each industry.

We cater to diverse mining operations and equipment manufacturing needs, including:

Our advanced CNC machining processes deliver precision-engineered components and assemblies designed specifically for heavy-duty mining machinery. Each part is crafted to meet the rigorous standards of the mining industry, ensuring exceptional durability, reliability, and performance even in the most extreme environments.

We manufacture robust drilling and excavation parts that are essential for efficient mining operations. Utilising state-of-the-art CNC machining, our tooling is engineered to optimise performance and extend service life, withstanding the relentless wear and high-impact forces encountered in both underground and open-pit mining.

Our precision-machined components for crushers and grinding machines are integral to processing raw materials effectively. Designed for continuous, high-load operations, these parts enhance equipment efficiency and reduce downtime, ensuring consistent performance in the demanding conditions of mining sites.

We produce high-accuracy, wear-resistant parts for conveyor systems and material handling equipment. Our CNC machined components are built to endure abrasive materials and heavy-duty usage, providing reliable support and improved operational efficiency throughout the entire material transport process.

Ordering from MK CNC Engineering is simple:

Contact us to discuss your requirements.

Collaborate with our engineers to finalise your product specifications.

We use advanced CNC technology to produce your parts with precision and care.

All products undergo rigorous testing for durability and performance.

We’ll arrange for prompt delivery of your mining tools and spare parts, ensuring they reach you securely and on time.

Using top-quality materials like high-strength alloys and wear-resistant steels, we ensure our products meet the rigorous demands of mining environments. Our advanced CNC machines, operated by skilled machinists, deliver precision results for every project.

Contact us today to discuss your project requirements and learn how MK CNC Engineering can enhance your mining operations.

Our CNC machining services consider various metallic, plastic, and composite materials to address a full range of materials involved, depending on the specific client project.

Lead times differ based on the complexity and dimension of the project. Our speed is prioritised since we will stay in touch with you to set a timeline geared toward making it all work for you.

Yes! From small prototype runs to massive runs, we can handle any size project consistently and efficiently.

Certainly! Our professional engineering team is available to partner with you to develop an exact version of the custom CNC machining services that fit the needs of your program.

What separates us from the rest all boils down to quality, innovation, and customer satisfaction. Advanced manufacturing technology plus a team of skilled professionals allow us to provide custom solutions that perfectly meet your specific needs.

Contact us today for precision CNC machining services for your mining needs. Call Us to discuss your project requirements and learn how MK CNC Engineering can enhance your mining operations.