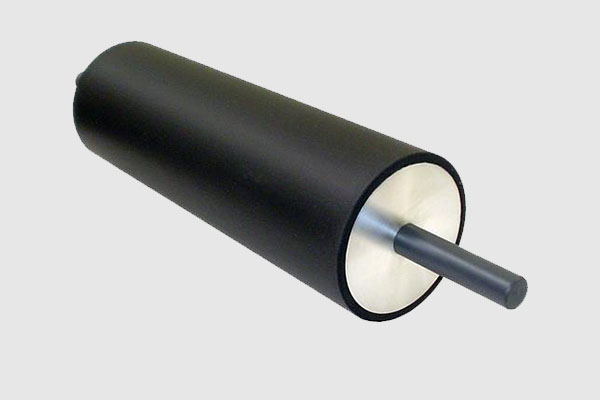

MK CNC Engineering is an Australian manufacturer specialising in high-quality rubber leg rollers. We possess extensive experience in crafting exceptional polyurethane and rubber roller coverings and custom-molded parts.

At MK CNC Engineering, we specialise in providing high-quality rubber leg roller manufacturing services in Australia. With a dedication to precision engineering and customer satisfaction, we have perfected the art of manufacturing quality polyurethane and rubber roller coverings, as well as custom-molded parts to meet the diverse needs of our clients.

MK CNC Engineering’s Expertise in Rubber Leg Rollers

MK CNC Engineering offers comprehensive services for rubber leg roller manufacturing in Australia. Their expertise likely encompasses:

Custom Design and Engineering : We can collaborate with you to design rubber leg rollers that perfectly match your specific requirements, including size, shape, durometer (shore hardness), and load capacity.

Material Selection : We possess knowledge of various rubber compounds suitable for leg rollers. These compounds might offer properties like wear resistance, elasticity, and grip, depending on your application.

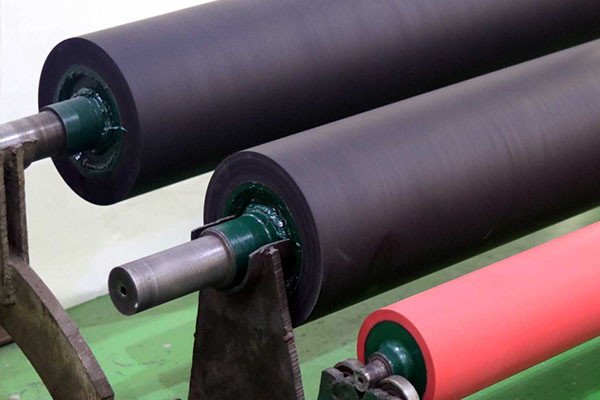

Manufacturing Processes: MK CNC Engineering can utilise various techniques to manufacture rubber leg rollers, potentially including:

Quality Control: Stringent quality control measures likely ensure that every rubber leg roller produced meets their high standards for performance and durability.

Get to MK CNC Engineering’s Best Solutions and Expertise:

Precision Manufacturing: With advanced manufacturing techniques, we excel in producing rubber leg rollers with exceptional precision and consistency. Whether you require standard sizes or custom specifications, our skilled engineers and craftsmen ensure that every roller meets the highest quality standards.

Quality Materials: We understand the importance of using quality materials in roller manufacturing. That’s why we source only the finest polyurethane and rubber compounds, known for their durability, resilience, and resistance to wear and tear. Our commitment to quality materials guarantees long-lasting performance and reliability in every roller we produce.

Custom Solutions: We recognise that every application is unique, which is why we offer custom solutions tailored to our clients’ specific requirements. Whether you need rollers for conveyor systems, industrial machinery, or material handling equipment, we work closely with you to design and manufacture rollers that perfectly match your needs.

Why Choose MK CNC ENGINEERING:

Partner with MK CNC ENGINEERING:

Experience the difference of working with a trusted partner for rubber leg roller manufacturing. Contact MK CNC ENGINEERING today to discuss your requirements and discover how we can help you achieve your goals with high-quality, custom-made rollers.

MK CNC ENGINEERING: Precision. Quality. Reliability in Rubber Leg Roller Manufacturing.

Our CNC machining services consider various metallic, plastic, and composite materials to address a full range of materials involved, depending on the specific client project.

Lead times differ based on the complexity and dimension of the project. Our speed is prioritised since we will stay in touch with you to set a timeline geared toward making it all work for you.

Yes! From small prototype runs to massive runs, we can handle any size project consistently and efficiently.

Certainly! Our professional engineering team is available to partner with you to develop an exact version of the custom CNC machining services that fit the needs of your program.

What separates us from the rest all boils down to quality, innovation, and customer satisfaction. Advanced manufacturing technology plus a team of skilled professionals allow us to provide custom solutions that perfectly meet your specific needs.