CNC Milling Services

The Precision Gap: Milling Problems We Solve

Even the smallest issue in CNC milling can derail your whole production line. Here’s how MK CNC keeps things running smoothly:

Inconsistent Quality

We maintain strict in-house inspections at every stage of production, ensuring each part meets your exact specifications before it leaves our workshop

Missed Deadlines

Our 24/7 Production Facility and flexible on-demand capacity mean your project stays on schedule—no surprises.

Costly Rework

We offer a First-Article Inspection Guarantee to catch issues before full-scale production, saving time and cost.

Limited Technical Expertise

Our Certified Engineers provide Design for Manufacturability (DFM) support to refine and optimise your parts before machining begins.

Why MK CNC?

Backed by a highly experienced team of engineers, tooling design experts, material science PhDs, and lean manufacturing specialists, we consistently deliver outstanding results.

Years of Experience

Projects Completed

On-Time Delivery Rate

Industries Served

Your Advantages with MK CNC

Exceptional Quality Control

Rigorous ISO-standard inspections, so you can trust that what arrives is exactly what you ordered with precise specifications.

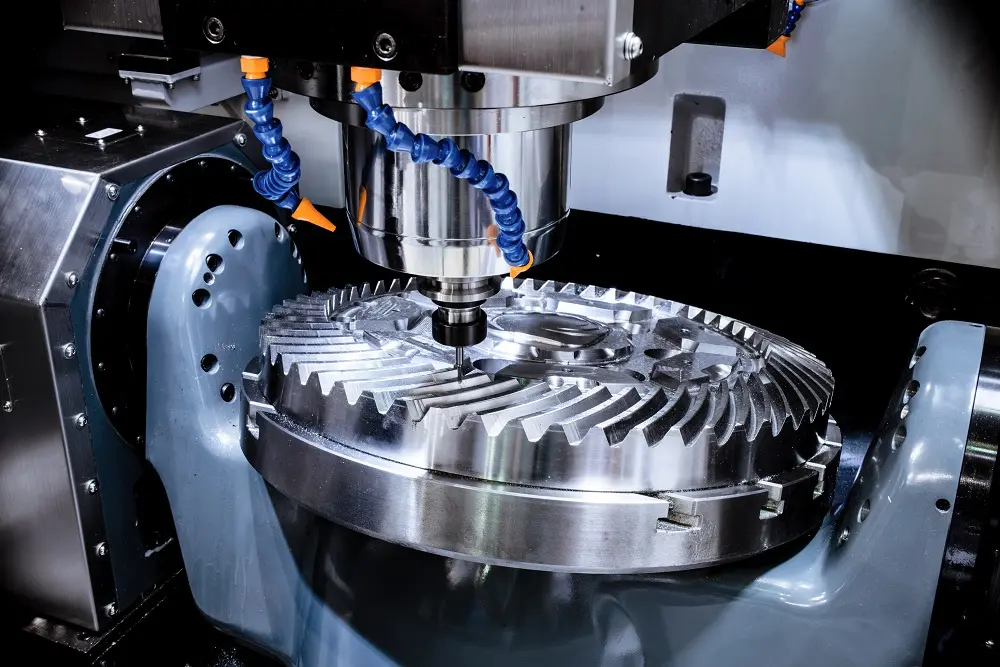

Advanced Technology & Cutting-Edge Equipment

Industry-leading machinery, including multi-axis CNC milling, guarantees precision and consistency.

Fast Turnaround & Reliable On-Time Delivery

Efficient 24/7 operations to meet your critical deadlines, maintaining consistent quality with regular updates.

Competitive Pricing through Cost-Effective Strategies

Flexible onshore and offshore manufacturing solutions personalised to your budget and scale.

Skilled, Experienced, and Certified Professionals

A highly trained team committed to excellence, backed by continuous professional certifications.

Customer-Centric Approach

Transparent communication, personalised service, and proactive support to ensure your success at every step.

Choose MK CNC for CNC milling excellence, where your toughest challenges become precision-engineered solutions.

Advanced CNC Milling Technology That Delivers Where It Matters

At MK CNC, we invest heavily in advanced CNC milling equipment to achieve unmatched precision and efficiency. Our facility features a versatile array of state-of-the-art machining centres, specifically engineered for flexibility, speed, and high-precision results.

Machinery Showcase & Capabilities

- Multi-Axis CNC Machines:

- 3-Axis, 4-Axis, and Advanced Milling: Even the most intricate parts are handled smoothly, with less setup time, better precision, and real cost savings.

- Vertical Machining Centres

- Versatile capabilities allow optimal tool access, rapid material removal, and high production throughput.

Key Differentiator: Dedicated Prototyping Cells vs. Production Lines

Unlike typical machining providers, MK CNC operates dedicated prototyping cells separately from our full-scale production lines. This ensures:- Rapid turnaround for prototypes, allowing quick validation of designs.

- High-volume efficiency without compromising the detailed attention that prototypes demand.

Advanced Machinery Gallery

- Ultra-Precision CNC Milling Machine (0.01mm Tolerance): Unparalleled accuracy for aerospace-grade precision.

- High-Speed Milling Centres: Specialised aluminium and composite machining, optimised for maximum productivity and quality.

- Titanium-Capable Mills with Cryogenic Cooling: Cutting-edge cryogenic systems allow precise machining of heat-sensitive materials, enhancing tool longevity and part accuracy.

- Micron-level tolerances are ideal for critical parts.

- Reduced cycle times with fewer setups.

- Exceptional surface finishes reduce secondary processes.

Integrated Technologies

We complement our milling operations with advanced supporting technologies, including:- CAD/CAM Integration: Advanced design software for optimal toolpaths and enhanced efficiency.

- EDM (Electrical Discharge Machining): Precision wire-cutting of intricate features.

- Precision Grinding: Achieving the final surface and dimensional accuracy required for critical applications.

Experience MK CNC's cutting-edge machining technology—precision, speed, and quality in every part.

Precision Milling Services Designed Around Your Needs

Core Offerings

High-Mix Prototyping

From 1 to 1,000 Units, we have a Zero Minimum Order Barrier (MOB). Quickly iterate your designs with rapid turnaround prototyping services.

Production Runs

Our automated pallet systems are built for high-volume jobs, keeping quality consistent whether you're ordering hundreds or thousands of parts.

Complex 3D Machining & Precision Detailing

We use advanced methods to replicate complex geometries with precise detailing, crisp edges, and smooth contours.

Complex Geometries

Multi-surface Contouring + Deep Cavity Machining. Achieve complex, multi-surface parts with fewer setups, reducing lead time and improving accuracy.

Materials Mastery

We expertly machine an extensive range of materials, including:

Metals

- Aerospace Grade Aluminium

- Inconel 718

- Aluminium Magnesium

- Titanium

- Steel

- Stainless Steel

- Brass

Plastics (Medical Grade & High Performance)

- PEEK

- Nylon

- Acetal

- PTFE (Teflon)

- Acrylic

- Other specialised plastics

Our specialists select optimal cutting parameters and tooling, ensuring precision results across all material types.

Guaranteed Precision Tolerances

We provide unmatched accuracy, consistently delivering. MK CNC enhances your CNC milling experience with comprehensive additional capabilities:

Professional Finishing Options

Polishing, Coating, Deburring—ensuring parts arrive assembly-ready.

End-to-End Support and Collaboration

Design for Manufacturing (DFM) consultation for optimal manufacturability and cost efficiency.

Post-Processing & Treatment

Anodising, Heat Treating, Surface Enhancement.

Full Assembly & Kitting

Streamlined assembly services, providing fully finished, ready-to-use kits or subassemblies.

Export Packaging for Offshore Clients

Secure, robust packaging meeting international shipping standards, ensuring your parts arrive safely worldwide.

At MK CNC, precision meets partnership. We're dedicated to delivering exactly what you need, precisely when you need it.

Industry-Specific CNC Milling Applications

Every industry has unique precision machining requirements—MK CNC deeply understands your industry-specific demands and standards.

Aerospace

- Unique Demands: Absolute precision, reliability in extreme environments, lightweight strength.

- Standards Met: Strict in-house quality checks, precision measuring tools, and consistent machining practices to achieve the accuracy aerospace components demand.

Medical & Healthcare

- Unique Demands: Impeccable cleanliness, precision, and biocompatibility of implants and instruments.

- Standards Met: Controlled machining environments, high-grade materials, and multi-stage inspections to ensure safe and precise parts for medical applications.

Mining & Energy

- Unique Demands: Highly durable, wear-resistant parts for extreme operational environments.

- Standards Met: Rigorous material selection and advanced heat treatments producing Wear-Resistant Components for harsh conditions.

Automotive

- Unique Demands: Precision, efficiency, lightweighting for performance and fuel economy (EV emphasis).

- Standards Met: Automotive standards compliance; specialised machining for EV Battery Housings & Lightweight Components.

Food & Beverage

- Unique Demands: Food-safe materials, easy-to-clean surfaces, corrosion resistance.

- Standards Met: FDA-compliant manufacturing, hygienic processing, and food-grade finishing for machinery components.

General Manufacturing & Consumer Products

- Unique Demands: Adaptability, consistent quality across diverse product lines.

- Standards Met: Quality assurance, flexible solutions for consumer electronics, industrial equipment, and any custom products.

The MK CNC Process

At MK CNC, every step is streamlined for your peace of mind from initial idea to final delivery.

Initial Consultation

Design Review

Material Sourcing

Pre-Production Planning

CNC Machining

Quality Assurance

Finishing & Post-Processing

Assembly & Kitting

Delivery & Logistics

After-Sales Support

Australian Precision, Global Reach – No Compromises

Many companies hesitate when it comes to offshore manufacturing, but MK CNC ensures you never sacrifice quality, control, or transparency, wherever your parts are machined.

Key Advantages of Our Offshore Process:

Identical QA Standards at All Facilities

We maintain consistent quality controls across all our offshore and onshore facilities.

Dedicated Export Team: Customs, Shipping & Tariffs

Expert handling of all international logistics ensures seamless, hassle-free global delivery. We manage customs compliance, shipping documentation, tariffs, and duties.

Currency-Flexible Billing (AUD/USD)

Simplified financial transactions with flexible billing options. Pay in Australian dollars or US dollars to match your operational needs.

Single Point-of-Contact

Receive streamlined communication with your dedicated Australian account manager coordinating global operations.

Real-Time Offshore Production Tracking

Maintain complete visibility of your offshore production progress, quality checkpoints, and shipping updates via our integrated tracking system.

Secure Export Packaging & Insurance

Robust packaging and shipping insurance guarantee your components arrive safely, securely, and in perfect condition.