CNC Turning Services

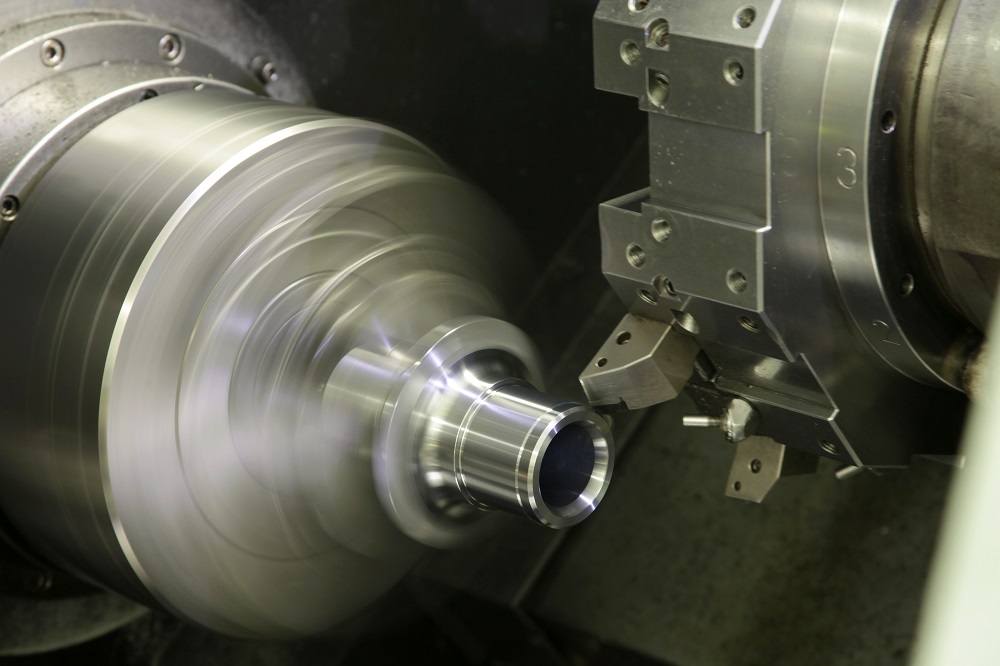

We provide CNC turning for accurate, repeatable cylindrical parts. Using multi-axis lathes with live tooling, we machine shafts, bushings, pins, couplings, and threads to achieve clean finishes and tight tolerances. Our programmers and inspectors control, measure and document each step from prototypes to large batches.

Our offshore model lowers costs without cutting corners. Efficient utilisation, skilled teams and bulk buying drive savings, while Australian oversight, first article approvals and CMM reports protect quality. Typical uses include aerospace fittings, medical hardware, mining components, automotive hubs, food-grade connectors and robotics parts. You get dependable results, clear updates and parts that fit first time.

The CNC Headaches You Shouldn't Be Dealing With

Even well-planned projects can stall when the turned parts are not consistent. We fix the typical headaches that slow teams down and push costs up.

Inconsistent dimensional accuracy

We stabilise process setup and tool paths so every part matches the drawing.

Poor surface finishes

Correct speeds, feeds and tool geometry deliver smooth, assembly-ready finishes.

Long lead times and high scrap rates

Lean programming, reliable fixtures and in-process checks keep parts flowing and reduce waste.

Difficulty machining exotic materials

Proven recipes for titanium, Inconel, duplex stainless and engineering plastics.

Limited in-house CNC lathe capacity

Flexible offshore capacity that scales with your demand.

Why MK CNC?

Backed by a highly experienced team of engineers, tooling design experts, material science PhDs, and lean manufacturing specialists, we consistently deliver outstanding results.

Years of Experience

Projects Completed

On-Time Delivery Rate

Industries Served

Your Advantages with MK CNC

Exceptional Quality Control

Rigorous in-process checks, calibrated tools and final inspection for every batch.

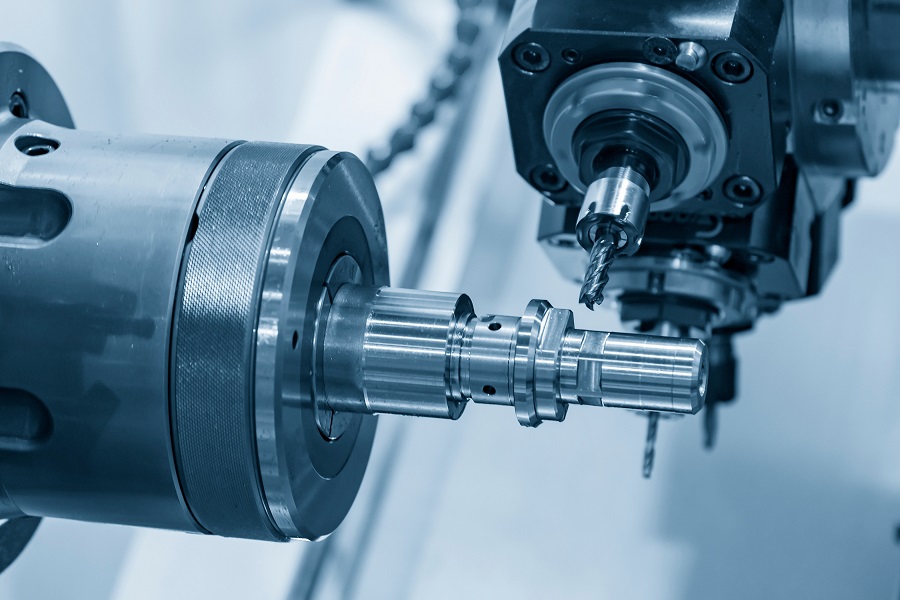

Advanced Multi-Axis Turning

Live-tooling lathes handle complex forms, cross-holes and threads in one setup.

Scalable Production

Reliable capacity for prototypes, small runs and high-volume schedules.

Rapid Lead Times & Support

Fast quoting, clear updates and a dedicated contact from kickoff to delivery.

Material Versatility

Confidence with aluminium, stainless, alloy steels, brass, copper, titanium and engineering plastics.

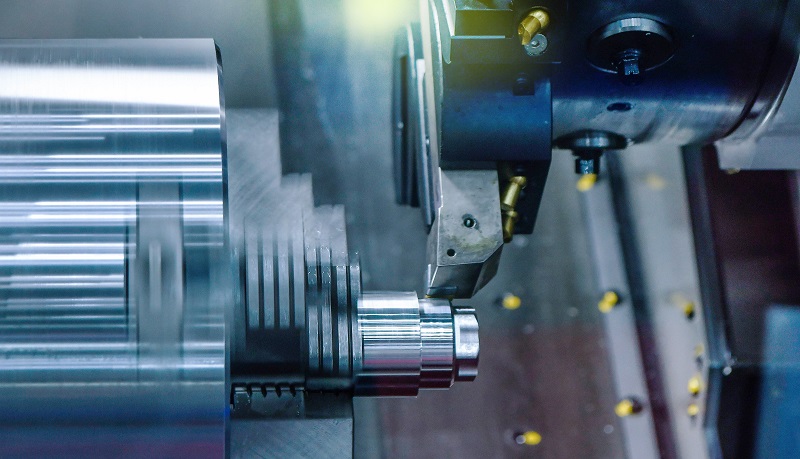

Comprehensive Finishing & Assembly

Threading, knurling, deburring, cleaning, sub-assembly and packing to your spec.

Competitive Offshore Pricing

Achieve lower total costs through efficient utilisation and skilled teams without compromising quality.

Global Supply Chain Coordination

Consolidated shipping, documents and tracking for smooth worldwide delivery.

Advanced CNC Turning Technology That Delivers Where It Matters

We invest in modern turning centres and strict process control so your parts meet spec the first time and every time. Our team programs, measures and verifies each step for repeatable results.- Live-tooling, multi-axis turning centres: Complex forms, cross-holes and threads completed in one setup for accuracy and speed.

- Tight tolerances with real-time measurement: In-process probing and SPC keep dimensions on target throughout the run.

- Automated bar feeding for high-volume work: Stable cycle times and fewer stoppages ensure reliable, high-volume output.

- Continuous monitoring and quality assurance: CMM checks, gauge R&R and documented inspections protect every batch.

Machine-Suited Prototyping to Calibrate Production Lines

Prototyping allows us to verify the setup, refine the program, and confirm the right tools and feeds before committing to full production. We remove guesswork early, so your line runs smoothly, parts pass inspection and schedules stay on track.- Rapi proof of concept: Cut sample parts quickly to validate design intent and tolerances.

- Repeaable accuracy across runs: Lock in stable fixtures, tool paths and offsets for consistent results.

- Advaned measurement and testing: Use CMM, surface roughness checks and material certificates to verify every critical feature.

Production & Finishing Solutions for CNC Turning

Great turning is only part of the job. We finish parts so they are clean, accurate and ready to assemble. Our team handles secondary operations in the same workflow, which shortens lead times and reduces handling.- Surface finishing: Deburring, polishing, bead blasting and brushing for controlled roughness and appearance.

- Threading and knurling: Internal and external threads, knurls for grip and fit, gauged to your specs.

- Drilling and tapping: Precise holes, spot faces and tapped features aligned to critical datums.

- Cleaning and packaging: Ultrasonic cleaning, rust prevention and protective packing to suit transport and storage.

Keeping machining and finishing under one roof improves workflow, reduces rework, and ensures every part matches the drawing.

Integrated Tech That Keeps Your Parts on Spec and On Time

We connect engineering, production and logistics so you have a clear status and full traceability from RFQ to delivery.- CAD and CAM programming: Efficient tool paths, verified setups and digital revision control.

- CMM inspection and SPC: First article reports, in-process checks and final inspection with records on file.

- ERP and supply chain tracking: Lot control, material certs and barcode traceability for each batch.

- Supplier and logistics management: Coordinated materials, finishing partners and freight with consolidated paperwork.

Experience Cutting‑Edge Turning Technology

Precision Turning Services Designed Around Your Needs

High Volume Production Turning

Rapid production runs with tight tolerances. Stable cycle times, controlled tools and in-process checks keep quality and delivery on track.

Prototyping

Small batch runs to prove designs and materials. Fast set-ups, clear feedback and first article reports help you lock specifications.

Continuous Manufacturing and Flexible Scheduling

Consistent output to match your timeline. We plan capacity, hold fixtures and adjust schedules so you stay supplied.

Custom Assemblies and Subcomponents

Integration of multiple turned parts. We add drilling, tapping, finishing and sub-assembly so parts arrive ready for your line.

Materials Mastery

Metals

- Aluminium 6061, 7075

- Stainless steel 303, 304, 316

- Mild and alloy steels

- Brass and bronze

- Copper

- Titanium

- Inconel and other high-temp alloys

Plastics and polymers

- Acetal (Delrin)

- Nylon

- PEEK

- PTFE

- PVC

- Acrylics

- Custom composites

We are confident with exotic alloys and hard-to-machine materials. Expect clean finishes, stable tolerances and full traceability from bar stock to final inspection.

Guaranteed Precision Tolerances

Trust us to hold size, roundness and finish on every batch. Each card below mirrors the icons in your design.

Unrivalled Turning Options

Micro work, multi-axis lathes and Swiss-type machines for fine detail and stable control.

Multi Axis CNC Turning and Live Tooling

Complex shapes, cross holes and threads in a single setup for accuracy and speed.

ISO Certified Processes and Traceability

Calibrated gauges, documented checks and full material and lot records from start to finish.

Full Customisation and Finishing

Bespoke grooves, radii, threads and surface treatments so parts arrive assembly-ready.

Strict Process Control and Continuous Improvement

SPC monitoring, first article approval and regular reviews that keep results repeatable.

Industry-Specific CNC Turning Applications

We support teams across many sectors with turned parts that meet strict specs, clean finishes and on-time delivery. Our engineers understand compliance, validation and documentation, so you get parts that fit, assemble and perform in the field.

Aerospace

Complex engine components, housings and high-strength fasteners. Capability in Aerospace Machining with first article reports and full traceability.

Medical and Healthcare

Surgical instrument handles, implants and fittings. Cleanroom-friendly packing and validated measurements on critical features.

Mining and Energy

Down hole components, shafts and couplings for harsh sites. Proven Mining Machining programs for tough alloys and high-load parts.

Automotive

Drive shafts, gear blanks and suspension parts. Stable cycle times, PPAP on request and consistent quality across batches.

Food and Beverage

Sanitary fittings and customised couplings, made to hygiene standards. Surface finishes verified for Food & Beverage Machining requirements.

Consumer Electronics and Robotics

Precision shafts, housings and bushings for compact assemblies with tight tolerances.

Industrial Machinery and Equipment

Rollers, pulleys and custom fasteners that keep plant uptime high.

General Manufacturing and Consumer Products

Reliable, cost-effective turned parts for a wide range of products, from fixtures to branded hardware.

The MK CNC Process

We keep things clear and predictable from the first chat to the final delivery. Here is how we move your job from idea to finished parts.

Initial Consultation and Requirements Gathering

Design Review and Engineering Analysis

Material Sourcing and Procurement

CNC Programming and Tooling Setup

Production Turning and In-Process Quality Control

Post-Machining Operations and Finishing

Secondary Operations and Assembly

Quality Inspection and Compliance Documentation

Packaging and Logistics Coordination

Sales Support and Dedicated Customer Care

Australian Precision, Global Reach – No Compromises

You get the best of both worlds. Local oversight, clear communication and parts that meet Australian expectations, paired with efficient offshore delivery. Ready to move forward with a reliable partner for turning?

Key Advantages of Our Offshore Process:

Immediate Cost Advantages

Lower total cost without losing precision or finish quality. Savings come from efficient machines, skilled teams and intelligent scheduling.

Uninterrupted Supply Chain and Inventory Resilience

Multiple qualified suppliers and safety stock planning reduce risk and keep parts moving.

Clear Communication and Local Project Oversight

Dedicated account managers in Australia guide the work, share updates and resolve issues fast.

Streamlined Logistics and Consolidated Invoicing

One point of contact for booking, documents, customs and billing. Simple, tidy and on time.

Single Source Efficiency

Quoting, machining, finishing and packing under one roof. Less handovers and clearer accountability.

Round-the-Clock Production

Time zone advantage with 24/7 manufacturing for quicker lead times and faster replenishment.